Acrylonitrile Butadiene Styrene (ABS) is a popular and widely used 3D printing filament due to its excellent mechanical properties and affordability. This thermoplastic material has been the go-to choice for many 3D printing enthusiasts and professionals alike. In this blog, we will provide an introduction to ABS as a 3D printing filament, discussing its properties, benefits, and best practices for achieving successful prints. We will also share some valuable tips and tricks to help you get started with ABS and optimize your 3D printing experience.

Understanding ABS as a 3D Printing Material

Properties of ABS

ABS is a petroleum-based thermoplastic that is both lightweight and durable. It is known for its high strength, impact resistance, and toughness, making it a suitable choice for a variety of applications. ABS is also resistant to chemicals and heat, which further expands its range of uses. It has a melting temperature between 210°C and 250°C, and typically prints at a bed temperature between 80°C and 110°C.

Advantages of ABS

Some of the main advantages of ABS as a 3D printing filament include:

- Strong and durable prints: ABS parts are known for their strength and durability, making them ideal for functional and mechanical components.

- Good layer adhesion: ABS has excellent layer adhesion, which results in strong, solid prints with few weaknesses between layers.

- Post-processing options: ABS can be sanded, painted, and vapor-smoothed with acetone, allowing for a variety of finishing options for your prints.

- Wide availability and affordability: ABS is readily available and often more affordable than other high-performance filaments, making it a popular choice for many users.

Preparing Your 3D Printer for ABS Printing

Choosing the Right Printer

To achieve successful prints with ABS, it's essential to choose a 3D printer that is compatible with this material. Some key features to look for in a printer suited for ABS include:

- Heated print bed: A heated print bed is crucial for preventing ABS prints from warping due to thermal contraction during the cooling process.

- Enclosed print chamber: An enclosed print chamber helps maintain a stable temperature throughout the printing process, which is essential for minimizing warping and improving print quality.

- Nozzle temperature range: Ensure that your printer's nozzle can reach temperatures between 210°C and 250°C, which is the recommended range for printing ABS.

Printer Settings for ABS

Before you start printing with ABS, it's essential to adjust your printer settings to optimize the print quality and minimize potential issues. Some key settings to consider include:

- Nozzle temperature: Set your nozzle temperature between 210°C and 250°C, depending on the specific ABS filament you are using. It's important to experiment with different temperatures within this range to find the ideal setting for your filament.

- Bed temperature: Set your bed temperature between 80°C and 110°C to ensure proper adhesion and minimize warping.

- Print speed: ABS prints best at a slower speed, typically between 40 and 60 mm/s. Slower print speeds allow for better layer adhesion and help prevent issues such as warping and delamination.

- Layer height: A lower layer height (0.1 - 0.2mm) can improve the print quality and strength of ABS prints, as it provides better layer adhesion and a smoother surface finish.

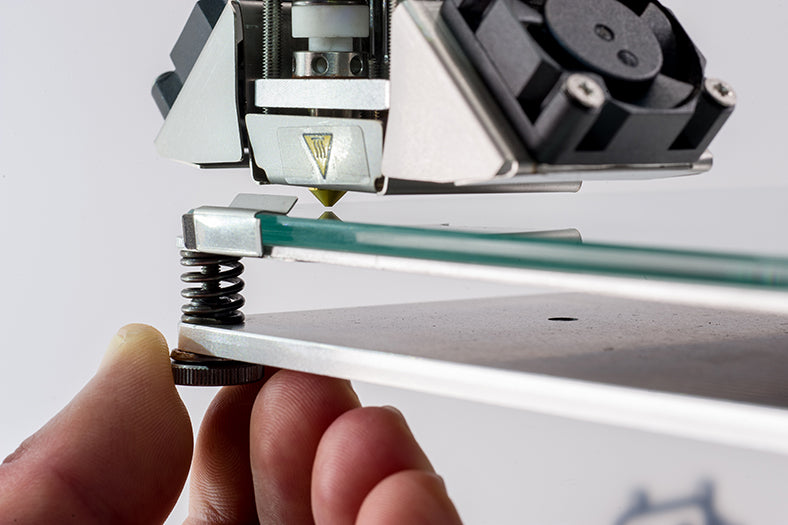

Bed Adhesion Techniques

Achieving proper bed adhesion is crucial for successful ABS prints, as it prevents warping and improves print quality. Some common bed adhesion techniques for ABS include:

- Bed surface material: Choose a bed surface material that promotes adhesion with ABS, such as glass, PEI, or BuildTak. Ensure the bed surface is clean and free of debris before printing.

- Adhesion aids: Apply adhesion aids like ABS juice (a mixture of ABS scraps dissolved in acetone) or glue stick to the print bed to enhance adhesion.

- Brim or raft: Adding a brim or raft to your print can increase the surface area in contact with the bed, helping to prevent warping and detachment.

Tips and Tricks for Printing with ABS

Controlling the Print Environment

Maintaining a stable and controlled print environment is crucial for minimizing warping and other print issues when using ABS. Some tips for controlling the print environment include:

- Enclose the printer: If your printer does not have an enclosed print chamber, consider building or purchasing an enclosure to help maintain a stable temperature and reduce drafts during the printing process.

- Minimize drafts: Locate your printer away from open windows, doors, and air vents to prevent drafts from affecting the print temperature and causing warping.

- Monitor ambient temperature: Maintain a consistent ambient temperature (ideally between 20°C and 25°C) in the room where your printer is located to ensure a stable print environment.

Filament Storage and Handling

Proper filament storage and handling are essential for achieving successful prints with ABS. Here are some tips for storing and handling ABS filament:

- Keep ABS dry: ABS is hygroscopic, which means it can absorb moisture from the air. Store your filament in a dry, cool place, preferably in a sealed container with desiccant packs.

- Avoid tangles: Ensure that the filament is neatly wound on the spool to prevent tangles and jams during the printing process.

- Regularly clean the nozzle: Keep your printer's nozzle clean and free of debris to ensure smooth extrusion and prevent clogs. Regularly perform cold pulls or use a cleaning filament to maintain a clean nozzle.

Troubleshooting Common ABS Printing Issues

When printing with ABS, you may encounter some common issues that can affect print quality. Here are some tips for troubleshooting these issues:

- Warping: To minimize warping, ensure that your print bed is level, properly heated, and coated with an adhesion aid. Adjust your print settings to use slower print speeds and consider enclosing your printer to maintain a stable temperature.

- Layer separation or delamination: If your print layers are separating or delaminating, try increasing the nozzle temperature to improve layer adhesion. Slower print speeds and a stable print environment can also help prevent this issue.

- Nozzle clogs: If your nozzle becomes clogged, try performing a cold pull or using a cleaning filament to remove the blockage. Keeping your filament dry and properly stored can also help prevent clogs.

Post-Processing ABS Prints

Sanding and Smoothing

Sanding is a common post-processing technique for ABS prints, as it can improve the surface finish and remove layer lines. Start with a lower grit sandpaper (e.g., 220 grit) to remove any rough areas or imperfections and gradually work your way up to a higher grit (e.g., 600-800 grit) for a smoother finish.

Acetone Vapor Smoothing

Acetone vapor smoothing is a popular technique for achieving a glossy, professional finish on ABS prints. This method involves exposing the print to acetone vapor, which dissolves the outer layer of the print, smoothing the surface and removing layer lines. This process can be done using a container and a small amount of acetone or a dedicated acetone vapor smoothing chamber. It's essential to use caution and proper safety measures, such as working in a well-ventilated area and wearing protective gloves and eyewear, as acetone is a volatile and potentially harmful chemical.

Painting and Finishing

ABS prints can be painted and finished to achieve a polished, professional appearance. Before painting, ensure that the print surface is clean and free of debris. You may need to apply a primer coat to help the paint adhere to the print surface better. Use acrylic or enamel paints for best results, and apply multiple thin coats, allowing each coat to dry thoroughly before applying the next one. Once the paint has dried, you can apply a clear protective sealant to enhance the durability and appearance of the finished print.

Section 5: Exploring the Potential of ABS in 3D Printing Projects (300 words)

Applications of ABS in 3D Printing

ABS is a versatile filament with a wide range of applications, from prototyping and functional parts to art and decorative pieces. Some common uses for ABS in 3D printing include:

- Prototyping: ABS is an excellent material for creating prototypes due to its durability, affordability, and ease of post-processing.

- Functional parts: ABS can be used to create mechanical components, gears, brackets, and other functional parts that require strength and durability.

- Custom enclosures: ABS is a popular choice for creating custom enclosures for electronics projects, as it provides a protective, durable shell that can be easily customized to fit specific components.

- Automotive components: ABS can be used to create replacement parts or custom modifications for automotive applications, thanks to its durability, impact resistance, and heat resistance.

- Art and decorative pieces: ABS can be used to create intricate, detailed sculptures, models, and other artistic pieces, as it is easy to post-process and finish.

Experimenting with ABS

As you gain experience and confidence with ABS, consider experimenting with different print settings, post-processing techniques, and applications to unlock the full potential of this versatile material. By continuously refining your skills and pushing the boundaries of what you can achieve with ABS, you can create stunning, high-quality 3D prints that showcase the unique capabilities of this popular filament.

ABS is a popular and versatile 3D printing filament with a wide range of applications and benefits. By understanding its properties, preparing your printer, and following best practices for printing and post-processing, you can achieve successful prints and unlock the full potential of ABS. With the tips and tricks outlined in this blog, you'll be well on your way to mastering the art of 3D printing with ABS and creating stunning, durable, and functional parts for a variety of projects. Embrace the challenges and opportunities that ABS offers, and let your creativity soar with this versatile material. We hope you have gained something new from reading this article. Happy printing!